OBJECTIVES

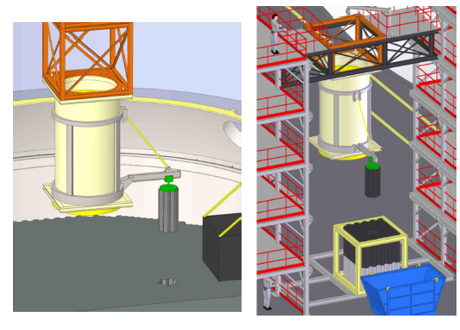

Simulation of graphite retrieval of Chinon A2 and tests to be performed in the industrial demonstrator.

INNO4GRAPH aims to develop a set of physical and digital tools and methods to be used in two different phases of European graphite reactor dismantling projects:

1.Tools and methods to be used during tests and studies upstream of the dismantling operations for:

- Decision-making: scenario grid analysis, mock-ups, digital tools, allowing to evaluate the efficiency of the use of innovative tools and more generally dismantling scenarios and to ensure optimal choices in terms of safety and cost-efficiency.

- Characterisation of the graphite properties: in-situ measurement of cracks and corrosion, digital 3D modelling and testing protocols for evaluation of the graphite mechanical properties, methodology for translating sample measurements to whole bricks, allowing to increase the efficiency of the dismantling operations by allowing an excellent knowledge of both the components of the facility to be dismantled and the dismantling tools.

- Innovative cutting and handling tools to be used during the dismantling operations.Simulation of graphite retrieval of Chinon A2 and tests to be performed in the industrial demonstrator.

EXPECTED IMPACTS

INNO4GRAPH will “stimulate innovation and promote a robust world leading decommissioning sector based on EU safety culture and know-how, taking advantage of promising innovative technologies that could contribute to timely and cost-efficient decommissioning on the basis of ensuring safety as well as protecting the workers, the public and the environment”.

The graphite reactor dismantling projects have not so far benefited from very wide publicity. There are many technological solutions, coming from the nuclear industry or other sectors (e.g. robotic industry), whose application potential have not yet been evaluated. The adaptation of these technologies to the specific problems of graphite thus presents a strong potential for innovation accessible in the short term. Good communication towards stakeholders from other related industries around the work carried out under the INNO4GRAPH project will help to stimulate this innovative ecosystem. Indeed, such a project is likely to attract innovators, including from non-nuclear industry.

HIGHLIGHTS

The potential for adoption of the innovations that will result from INNO4GRAPH is strong since this project is supported by all graphite generator reactor operators in Europe.

INNO4GRAPH developments and the subsequent full-scale demonstrator will significantly contribute to mitigating safety risks related to the extraction and handling of graphite, during the dismantling process, such as inflammatory risks or explosion, risks for contamination etc. By developing tools which will provide more in-depth information about the graphite mechanical properties and tools that will decrease the risk of handling radioactive material, the safety of the dismantling operations will be increased.

PARTNERS

EDF / ENRESA / GRAPHITECH / Cyclife Digital Solutions / CEA / SOGIN / LEI / CIRTEN-POLIMI / University of Manchester / Westinghouse Electric Spain / Ansaldo Nucleare / Tecnatom / Arttic

DURATION & BUDGET

September 2020 – August 2023 – 3 years

3 813 659,25 €

CONTACT

Technical Project Leader:

Michèle Guerin (EDF)

Email: michele.guerin@edf.fr

FOR DOWNLOAD

WEBSITE AND SOCIAL MEDIA

Check out the project website.

Follow the project on LinkedIn and Twitter.

This project has received funding from the Euratom research and training programme 2014-2018 under grant agreement No 945273