SPCMIATF Project

What is SPCMIATF?

Accident Tolerant Fuel claddings are engineered to address the inherent deficiencies of Zirconium alloys by reducing the metal–water reaction. As a short-term solution, the coating’s stability above 1200 °C in high steam pressure and compatibility with coolant must be ensured. Consequently, only thin (<50 µm) chromium coating is considered viable for Pressurized Water Reactors (PWRs). While, to guarantee functionality under all operating modes, coating integrity must be verified, particularly under Normal Operating Conditions (NOC), since any failure in this phase would lead to Prior to Accident Failure Condition (PAFC).

Since the chromium layer is thin, conventional PWR phenomena remain applicable. Under NOC, Pellet Cladding Mechanical Interaction (PCMI) is unavoidable. Radial cladding expansion from pellet swelling may theoritically initiate coating cracking, further intensified by higher burnup levels and load-following operation.

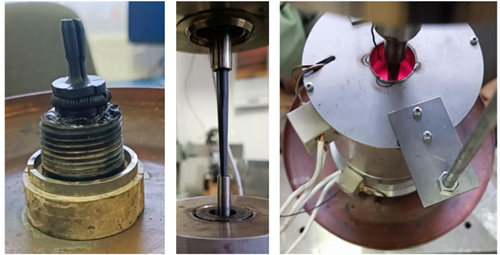

To investigate this hypothesis, segmented-mandrel ductility test that mechanically simulates pellet swelling by controlled radial displacement of a multi-segment tool was implemented.

The technical focus was to select reperesentative test parameters, executoin, numerical analysis of the test supported by novel 3D-Finite Element (FE) model, followed by post-test characterization of unirradiated coated and uncoated claddings.

The objective was to quantify and simulate mechanical response, deformation capability, and coating failure modes under imposed radial displacement, while developing a FE model coupled with the fuel performance code of TRANSURANUS, using a innoative code coupling to assess mechanical sub-models. Post-test characterization included Scanning Electron Microscopy (SEM), Light Optical Microscopy (LOM), metallography, and high-temperature oxidation of coated specimens.

SEM and LOM identified the presence, location, and morphology of cracks. Subsequent oxidation at 1000 °C for 1800 s in steam, simulating conservative LOCA conditions, examined the effect of pre-existing defects on oxidation kinetics and scale adherence. Metallography assessed microstructural evolution, nodular oxidation, oxygen stablized region crack propagation, and interdiffusion of Zr into coating containing nitiride.

Figure 1 : Mandrel ductility test configuration (Figure 27 of the report)

Objectives

The main objective of the proposed test series is to check if the chromium coating on the zirconium cladding alloy surface would flexibly follow the strain of the cladding tube in a simulated PCMI transient with little deformation, or the coating would break up into stripes of coated and uncoated segments.

Main outcomes

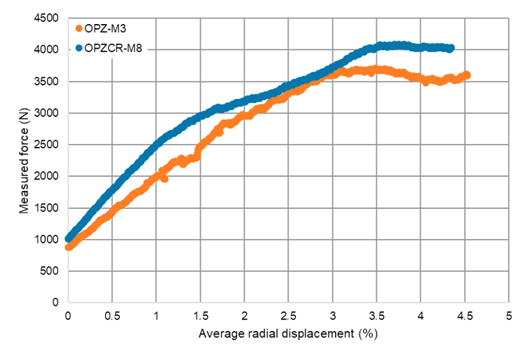

- The mandrel ductility test campaign produced a detailed dataset across 19 experiments, providing valuable insights into the mechanical behavior of both chromium-coated and uncoated ATF cladding samples.

- Scanning electron microscopy (SEM) revealed distinct cracking behaviors in chromium-coated samples, showcasing how the coating behaves under mechanical stress and demonstrating no macroscopic delamination. Moreover, the Cr layer on the external surface of the coated specimens did not remain fully intact: small cracks could be observed in the post-test examinations using optical and scanning electron microscopy.

- Post-test oxidation in steam highlighted the role of the chromium oxide layer in facilitating deeper oxygen penetration and compromising zirconium’s structural integrity (cracking) beneath the coating. At the bottom of the cracks intense localized oxidation of zirconium cladding took place.

- The CrN coating resulted in the formation of Zr nitride during steam oxidation after mandrel tests.

- The mechanical test indicates that, at 300 °C, the chromium layer does not follow the stress-strain curve of bulk chromium. The formation of cracks suggests that grain boundaries may contribute to the initiation of failure conditions at the grain level.

Figure 2 : Force average radial displacement of the coated and uncoated Opt ZIRLO samples (Figure 28 of the report)

Publications

- H. Yousefi: Master of Science Thesis “Simulation of pellet-cladding mechanical interaction with accident tolerant fuel cladding” University of Pisa- HUN REN Centre for Energy Research 2025-11-30

- P. Aragón, H. Yousefi, A. Schubert, P. Van Uffelen: Mandrel Test Simulation Using The TRANSURANUS Code: Insights From The Offer Project (IAEA Technical Meeting on Advanced Technology Fuels, Vienna, 28-31 October 2025)

- M. Király, H. Yousefi, Z. Hózer, T. Novotny, E. Perez-Feró, A. Pintér-Csordás, N. Vér: Testing-Simulation of Pellet-Cladding Mechanical Interaction with ATF Claddings (IAEA Technical Meeting on Advanced Technology Fuels, Vienna, 28-31 October 2025)

- H. Yousefi, R. Lo Frano, M. Király, Z. Hózer, L. Tatár, F. D’Auria, D. Antok, N. Forgione: Finite Element Simulation of Mandrel Test with ATF Cladding (IAEA Technical Meeting on Advanced Technology Fuels, Vienna, 28-31 October 2025)

- H. Yousefi, Z. Hózer, R. Lo Frano, M. Király,L. Tatár,N. Vér, F. D’auria,N. Forgione, P. Aragon, P. Van Uffelen: Simulation of Pellet-Cladding Mechanical Interaction with Accident Tolerant Fuel Claddings (SCOPE-2 Conference, Dhahran, Saudi Arabia, 2-6 November, 2025)

- Future Journal papers ( date and name have to be decided)

Interest for use of reached results

EDF, Westinghouse, Universitá di Pisa, HUN-REN-Centre for Energy Research, CTU, EPFL, JRC-Karlsruhe, and other oganizations.