NIPES Project

What is NIPES?

In the framework of the desired extension current nuclear power plants (NPPs) life, all the pieces of equipment inside the plants should be tested and their reliability verified.

Among others, low voltage cables play a very important role in guaranteeing adequate operating life of the NPPs. Early failure of cables important to safety could lead to unexpected power loss, lack of communication and, in the worst case, to a nuclear accident. Proper functionality of cables is ensured by the insulating polymer layer next to the conductor. This material degrades throughout the application life of the cable due to the enhanced environmental stresses i.e., radiation, heat, moisture, and chemical sprays in nuclear environments. The NIPES project aims at investigating the effect of radiation and heat on typical polymeric materials used inside NPPs e.g., XLPE (cross-linked polyethylene), PVC (polyvinyl chloride) and EPDM (Ethylene-Propylene Diene Monomer).

Objectives

The NIPES project aims at investigating the effect of radiation and heat on typical polymeric materials used inside NPPs e.g., XLPE (cross-linked polyethylene), PVC (polyvinyl chloride) and EPDM (Ethylene-Propylene Diene Monomer).

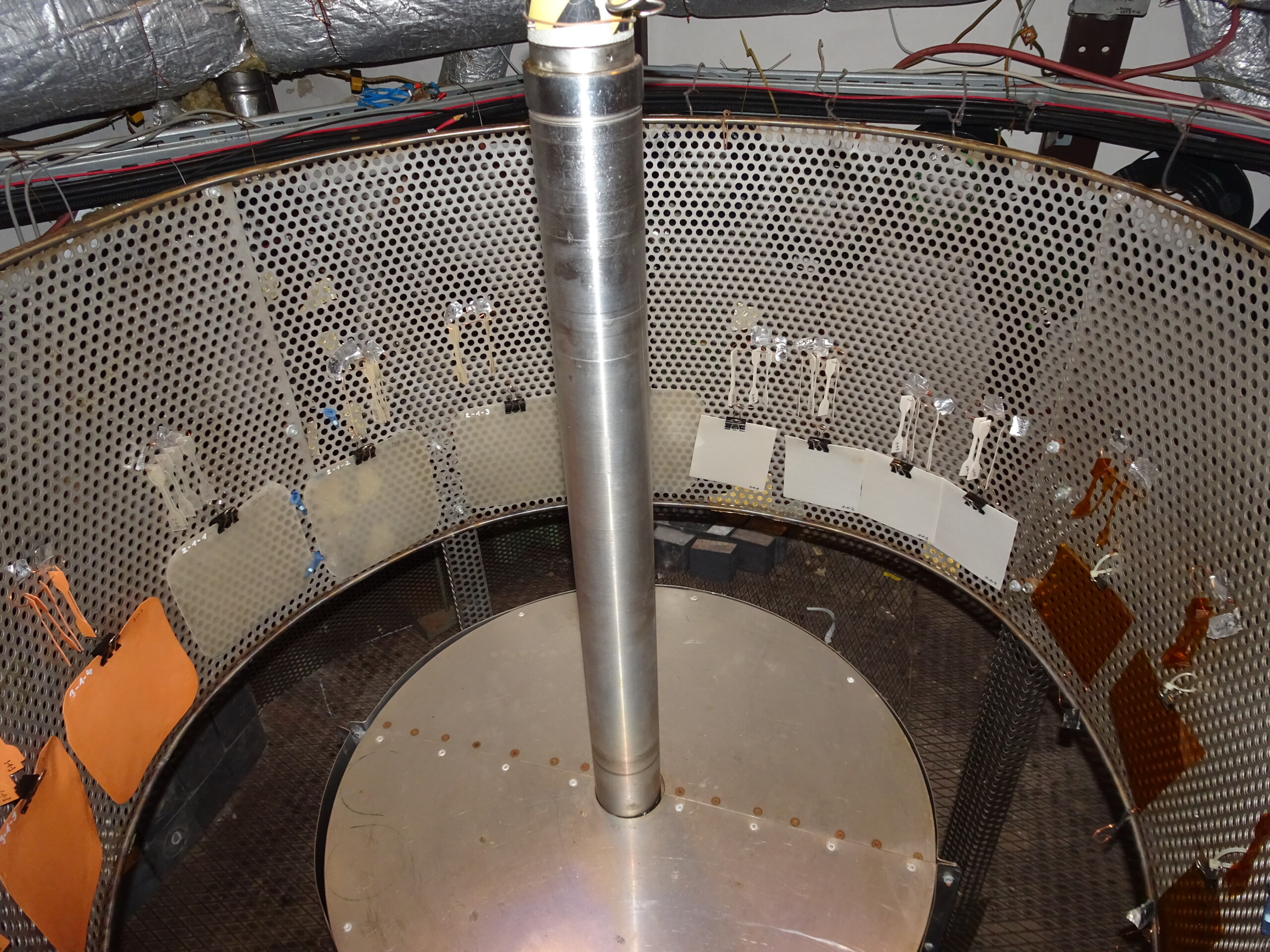

Inside the project, flat sheets will be aged inside an irradiation chamber under accelerated conditions to simulate degradation on the materials equivalent to real environment.

Aged materials will be characterized with both conventional destructive testing techniques (e.g., tensile tests) and non-destructive (ND) ones e.g., dielectric spectroscopy and electrical conductivity. The correlation among techniques will open the possibility to monitor and assess cable health trough NDTs and plan the maintenance or substitution of the related equipment. Finally, a phenomenological life model will be built based on the experimental results obtained. This would allow the estimation of the life of the electrical equipment under service and accelerated aging conditions.

Main outcomes

Main outcomes of the project may be summarized as follows:

- Validation of the use of dielectric spectroscopy as a nondestructive condition monitoring technique for various insulating material. The approach validated on XLPE has been efficiently extended to EPDM, while PVC showed a different behavior which follows with aging state.

- Validation of the correlation of the dielectric spectroscopy technique with state of the art condition monitoring tests (e.g., EaB and FTIR analyses).

- Crosscorellation among different electrical tests (namely DC conductivity, dielectric spectroscopy and AC breakdown) in order to evaluate electrical degradation and breakdown mechanism of the insulation.

Publications

- V. Suraci, J. Jin, D. Fabiani “Electrical characterization of EPDM-based insulation systems through high voltage dielectric spectroscopy and space charge analyses“ – 2024 IEEE International Conference on High Voltage Engineering and Applications (ICHVE) (doi: 10.1109/ICHVE61955.2024.10676121).

- Jin, S.V. Suraci, D. Fabiani “Non-destructive assessment of thermally aged polyimide films using electrical properties” – 2025 IEEE Conference of Electrical Insulation and Dielectric Phenomena (CEIDP) – to be published.

- Jin, S.V. Suraci,D. Fabiani “Evolution of electrical properties due to combined effects of radiation and high temperature aging on EPDM insulation systems“ – 2025 IEEE Conference of Electrical Insulation and Dielectric Phenomena (CEIDP) – to be published.

- J. Jin, D. Fabiani, S.V. Suraci “High-Temperature performance of polyimide under accelerated thermal aging: linking microstructural changes to macroscopic electrical properties“ – Wiley IET High Voltage – under revision

Interest for use of reached results

NPP facilities that have developed cable ageing management programme (CAMP).

Bellow mentioned entities knows results:

- EDF.

- ÚJV Řež. ÚJV has developed CAMP for ČEZ and it is still the main contractor in this topic.