HyAMsteel Project

What is HyAMsteel?

Ensuring the safe long-term operation of nuclear power plants (NPPs) requires a combination of asset management, obsolescence management, maintenance, and equipment reliability, which remains a technical challenge for European NPPs. Conventional manufacturing processes consumes significant time and resources. Laser-based powder bed fusion (LPBF or PBF-LB) is the most widely applied additive manufacturing (AM) technique in the nuclear industry. LPBF possesses the unique capability to produce near-to-shape components in a one-step manufacturing process, followed by post-processing steps.

Hydrogen uptake in a nuclear reactor environment occurs due to prolonged exposure to a high-temperature aqueous environment. In some cases, hydrogen levels can exceed the critical concentration for hydrogen embrittlement (HE). To date, no systematic research has been conducted to understand how post-additive manufacturing heat treatments influence hydrogen trapping and diffusion behavior, and the potential for local HE in LPBF 316L stainless steel. A comprehensive understanding of the mechanical behavior of LPBF stainless steels after heat treatments in a hydrogen-containing environment is crucial for assessing their performance and reliability, especially in light water reactor (LWR) environments containing hydrogen.

Objectives

The HyAMsteel project progressed very well and the planned tests and advanced microstructural characterizations have progressed even slightly ahead of the planned schedule. The goals set in the project proposal were accomplished without deviation.

Main outcomes

The hydrogen effect on dislocation arrangement, martensite phase formation and subsequent plastic deformation will be further investigated. The visit of NTNU researcher to VTT characterization platform was a great success with a lot of scientific and engineering results.

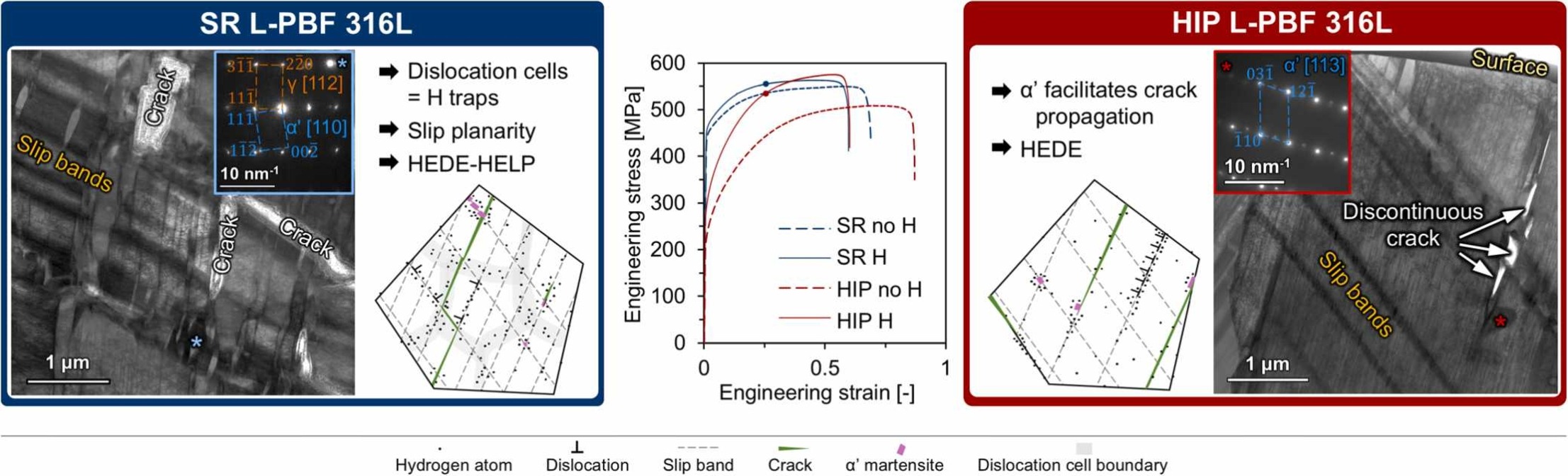

An in-depth characterization was performed to examine the degradation of laser powder bed fused (L-PBF) 316L austenitic stainless steel upon galvanostatic hydrogen charging, using high resolution microstructural characterization techniques. The hydrogen embrittlement of stress relieved (SR) and hot isostatic pressed (HIP) L-PBF 316L austenitic stainless steel was focused to gain an in-depth understanding of the hydrogen embrittlement mechanism and its intercorrelation with the microstructure. The difficulty lies in the highly complex microstructure of the studied materials and the complex interaction with hydrogen. It was handled with the careful design of experiments and throughout analysis and timely discussions.

The results were summarized and delivered as an oral presentation in the European Conference of Fracture (26-30 August 2024) and EUROCORR Conference (8-11 September 2025). The team published the manuscripts in Corrosion Science and Procedia Structural Integrity in 2025.

Publications

[1] On the improved hydrogen embrittlement resistance in stress relieved laser powder bed fused 316L stainless steel over the hot isostatic pressed equivalent, Corrosion Science, 2025, https://doi.org/10.1016/j.corsci.2025.113159Get rights and content

[2] Hydrogen interaction with post-processed L-PBF 316L stainless steel, Procedia Structural Integrity, https://doi.org/10.1016/j.prostr.2025.06.172

Interest for use of reached results

Steel companies, Materials Science department of different universities.