EXCEPTION Project

What is EXCEPTION?

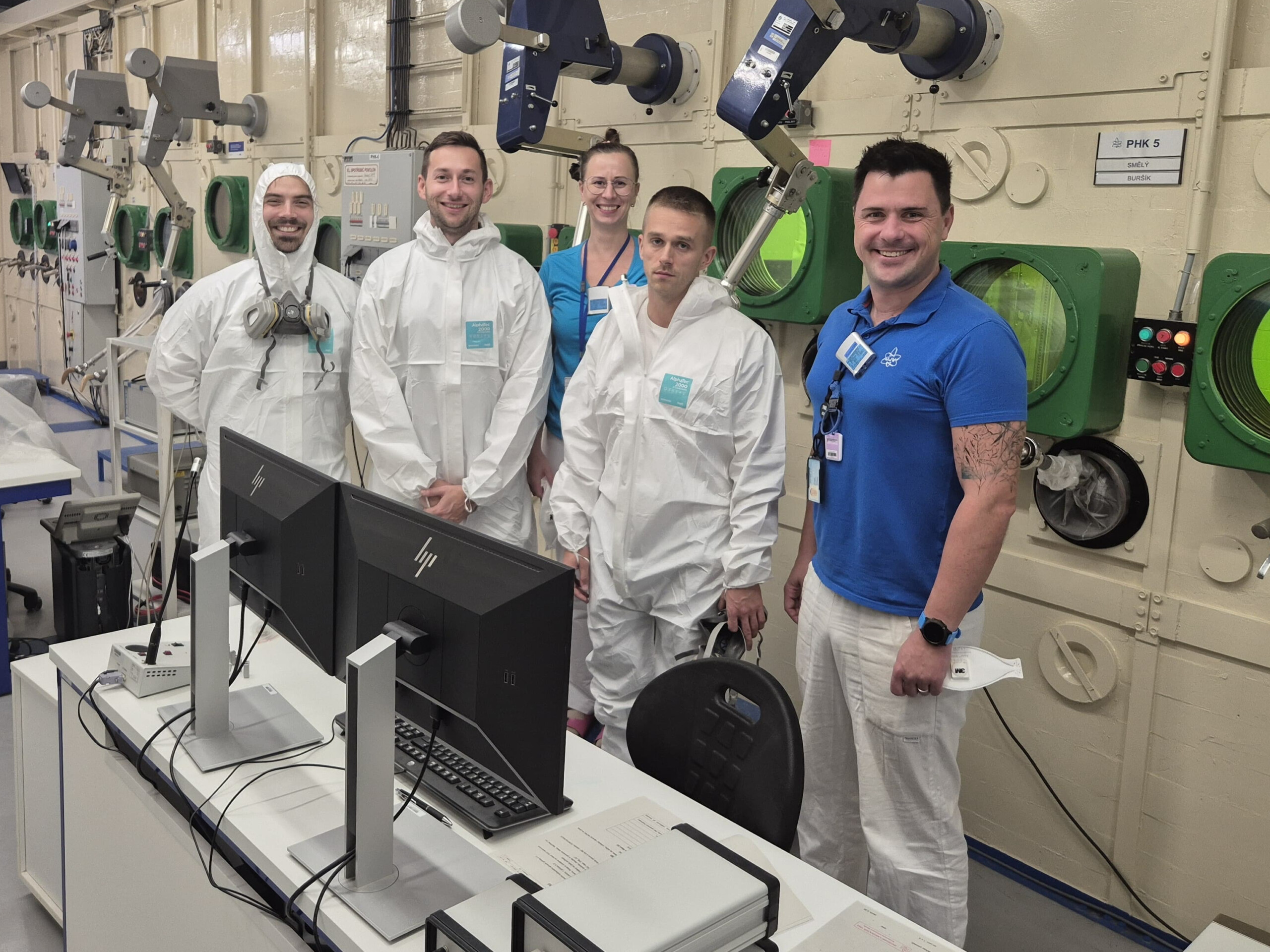

This project is focused on the hands-on training and development of young professionals in the field of nuclear engineering and materials science, with a particular focus on the mechanical testing of structural materials from nuclear power plants (NPPs). Motivated by the need to manage aging and optimize the operational lifetime of NPP units, the initiative leverages unique opportunities presented by the decommissioning of V1 units in Slovakia. Original archive materials, extracted from primary circuit components that have endured decades of real operational conditions, serve as invaluable resources for both research and education. By collaborating with renowned institutions such as VUJE and the accredited laboratories of UJV Rez, the project ensures that participants gain exposure to advanced methodologies and quality assurance frameworks in mechanical testing, including static fracture toughness, tensile testing, and instrumented impact testing.

The project’s primary motivation lies in addressing the challenges of assessing material degradation under authentic service conditions, which is essential for ensuring the safety, reliability, and longevity of nuclear power plants. Through experimental programs grounded in international standards, participants will acquire critical skills in specimen preparation, testing procedures, data analysis, and reporting—aligning with the latest developments in global quality management. The initiative not only provides practical knowledge transfer regarding the implementation and context of technical standards (ASTM, ISO) but also fosters interdisciplinary collaboration and problem-solving among researchers from diverse backgrounds. Ultimately, the project aims to produce unique, real-world data on the effects of long-term operation on NPP materials, supporting ongoing safety assessments and the regulatory approval process for continued plant operation, while cultivating a new generation of experts equipped to meet future industry challenges.

Objectives

The primary aim of the project is to deliver comprehensive, hands-on training to young professionals in nuclear engineering and materials science, with a focus on mechanical testing of structural materials from the primary circuit of nuclear power plants. By utilizing original archive materials extracted from decommissioned and operating units, participants gain invaluable experience in specimen preparation, testing procedures, and data analysis under real operational conditions. The project emphasizes adherence to international quality assurance standards, ensuring that all processes—from specimen manufacture to test execution—are conducted with accuracy, traceability, and reliability.

Specific objectives include equipping trainees with practical skills in mechanical testing, such as impact, tensile, and static fracture toughness tests, using state-of-the-art methodologies and equipment in an accredited laboratory. The project also stresses the importance of quality assurance, documentation, data collection, and reporting, aligned with ISO and ASTM standards. Another key goal is to foster interdisciplinary collaboration, encouraging participants from diverse backgrounds to engage in problem-solving and share perspectives on material testing challenges.

A unique aspect of the project is its focus on analysing real operational components, yielding insights into the actual degradation and performance of safety-critical materials over extended service periods. These findings will inform periodic assessments and regulatory decision-making regarding the continued safe operation of nuclear power units. Overall, the project represents a synergy of education, research, and international cooperation, preparing the next generation of experts to uphold and advance safety and reliability in the nuclear industry.

Main outcomes

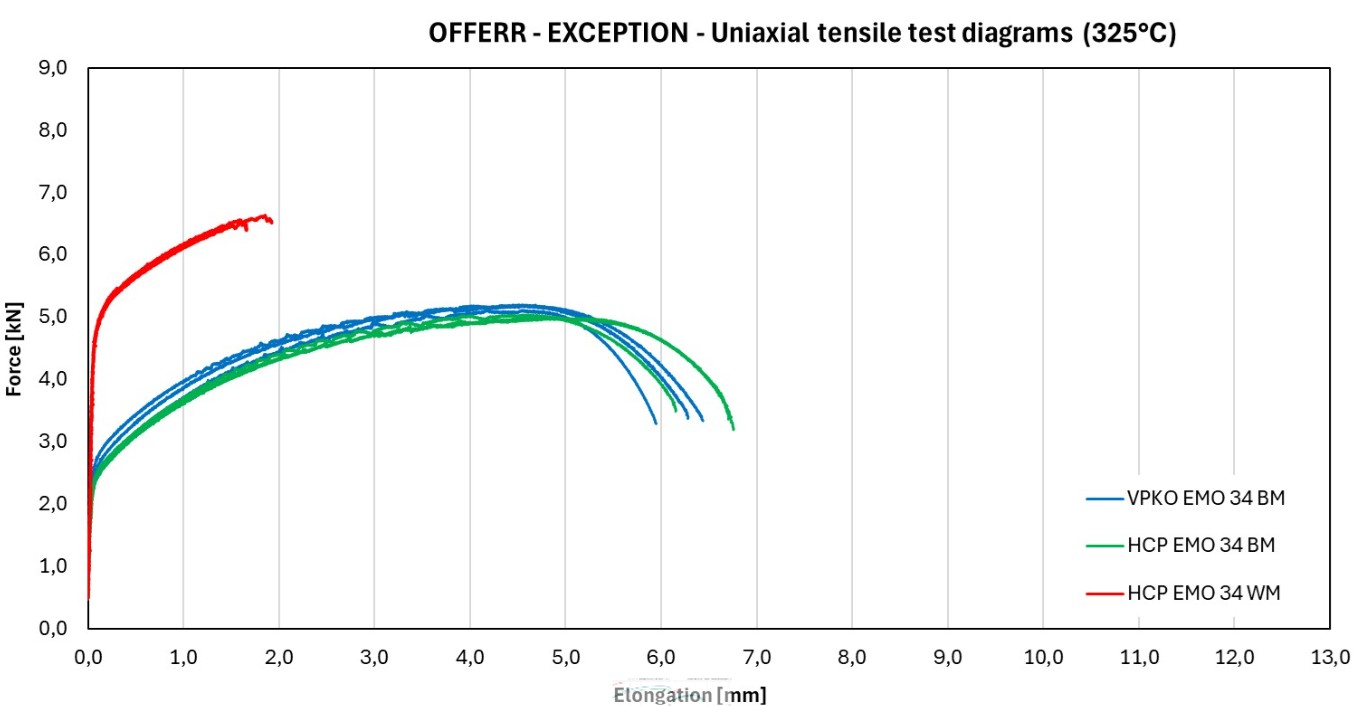

Among the main achievements are the practical training of young nuclear engineers in performing mechanical tests such as impact, static fracture toughness, and tensile testing, as well as the testing of original piping material from the new units of the EMO34 nuclear power plant, allowing for long-term operational effects on these components to be tracked. The project also contributed to workforce development by enabling a new generation of nuclear specialists to gain valuable hands-on experience, and the expansion of the database of nuclear power plant structural material properties allows for a more comprehensive understanding of their behaviour in operation.

Publications

The project proposal did not foresee any publications.

The key technical outputs will be presented to representatives of the power plant operator, SE, a.s., during a specialized technical seminar entitled “Utilization of Results from Tasks Carried Out in the Structural Analysis and Control Departments for the Reliable and Safe Operation of Nuclear Power Plants,” to be held on 26–28 November 2025.

Interest for use of reached results

VUJE, a.s., SE, a.s., ČEZ, a.s.