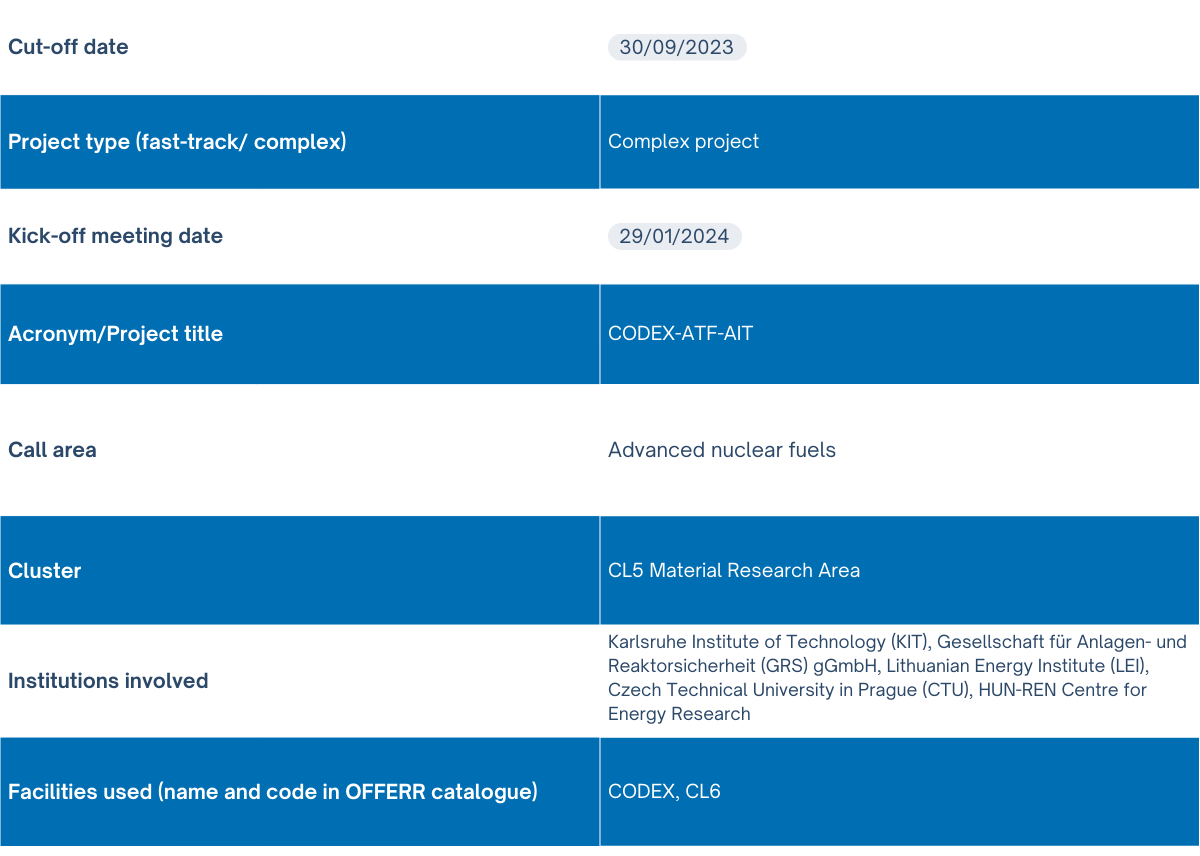

CODEX-ATF-AIT Project

What is CODEX-ATF-AIT?

The CODEX-ATF-AIT integral air ingress experiment was successfully conducted at the HUN-REN Centre for Energy Research (HUN-REN EK) in Budapest. The experimental scenario was designed to investigate key phenomena of fuel rod behavior during accident conditions, including cladding burst, oxidation, nitriding, and eutectic formation. During the preparatory phase, the facility was heated to 600 °C under a steam-argon atmosphere. In the subsequent pre-oxidation phase, the rod heating power was increased stepwise, leading to pressurization and cladding burst between 750–800 °C in most rods. The burst openings allowed coolant ingress, initiating chemical reactions on both sides of the cladding.

In the air ingress phase, the temperature rise was significantly slower and smoother compared to the reference experiment CODEX-AIT-3, demonstrating the protective effect of the Cr coating. The duration of the air ingress phase was extended to 1.5 hours (compared to 1 hour in the reference test), with a maximum cladding temperature of 1545 °C (compared to 1600 °C). The temperature profile shifted during this phase, with the peak moving from the upper bundle section to lower elevations due to intense chemical interactions in the less oxidized regions.

Gas analysis confirmed steam and oxygen starvation conditions during air ingress. The partial consumption of nitrogen indicated nitride formation. A total of 1.4 g of hydrogen was generated during the pre-oxidation phase, followed by 3.3 g during the air ingress phase. A controlled cool-down in argon flow was performed to avoid further reactions.

Post-test examinations (endoscopy, light optical microscopy, scanning electron microscopy, energy-dispersive X-ray spectroscopy) were performed to identify degradation mechanisms.

The results confirm the protective role of Cr coating under air ingress conditions and provide detailed insight into the associated complex material interaction phenomena.

Objectives

The introduction of accident-tolerant fuel (ATF) at nuclear power plants requires testing under a wide variety of accident conditions. The most promising near-term ATF cladding solution is Cr-coated zirconium alloys.

The main objective of the CODEX-ATF-AIT test was to investigate the behavior of Cr-coated cladding under air-ingress severe accident conditions. The access of air to the hot surface of fuel rods during accidents may significantly accelerate core degradation after the failure of the Cr coating, due to the intense oxidation of zirconium alloys. Scenarios leading to air ingress (such as lower head failure, open reactor, or spent fuel storage pool accidents) can be critical from the point of view of radiological consequences, since the loss of cladding integrity can lead to the oxidation of ruthenium and the formation of gaseous radionuclide species.

It was expected that a comparison with the reference test CODEX-AIT-3, carried out with uncoated cladding tubes, would provide information on the role of Cr coating in accident progression and fuel degradation phenomena, and that conclusions could be drawn on the potential extension of coping time.

Main outcomes

An air ingress experiment was performed in which the experimental bundle was assembled from chromium-coated rods. By comparison with the previous experiment (CODEX-AIT-3), in which no chromium-coated rods were included, the usefulness of chromium coating on fuel element tubes could be assessed.

The bundle was successfully assembled, and during the test the maximum set temperature was reached. Measurements were conducted in the reference atmosphere. The internally pressurized fuel rods were ballooned and burst, allowing the inner surfaces of these rods to chemically react with steam and air. In comparison with the reference test (CODEX-AIT-3), it was observed that the chromium layer proved beneficial, as high-temperature escalation was delayed and the rod surfaces were protected by the coating. The CODEX-ATF-AIT experiment also revealed that very high temperatures could lead to Cr-Zr eutectic formation and local melting on the surfaces of chromium-coated components.

In the case of a nuclear power plant accident, the application of chromium coating could extend the coping time in air ingress type severe accidents, thereby allowing additional time for mitigation actions by the staff.

Results

Publications

- Z. Hózer, R. Farkas, N. Vér, B. Bürger: CODEX-ATF: Integral Bundle Test With Accident Tolerant Fuel, Proceedings of TOPFUEL 2024, Grenoble, ENS

- R. Farkas, N. Vér, B. Bürger, A. Pintér Csordás, L. Illés, Z. Hózer, U. Stegmaier: The CODEX-ATF-AIT integral air ingress experiment, 29th International QUENCH Workshop, Karlsruhe, 2024-11-19

- Róbert Farkas, Nóra Vér, Berta Bürger, Zoltán Hózer: Post-test examination of the integral air ingress experiment CODEX-ATF-AIT, 30th International QUENCH Workshop, Karlsruhe, 2025-12-16

- Z. Hózer, R. Farkas, N. Vér, B. Bürger, A. Pintér-Csordás, M. Király, P. Szabó, S. E. Habbachi, M. Ševeček, M. Steinbrück, J. Stuckert, M. Grosse: Integral Testing of ATF Fuel under High Temperature Accident Conditions in the CODEX Facility, (IAEA Technical Meeting on Advanced Technology Fuels, Vienna, 28-31 October 2025)

- Róbert Farkas, Nóra Vér, Berta Bürger, Zoltán Hózer: The integral air ingress CODEX-ATF-AIT experiment, 12th European Review Meeting on Severe Accident Research Conference, Madrid, 2026-05-18

Interest for use of reached results

Manufacturers of Cr-coated cladding as Westinghouse and Framatome

Users and developers of severe accident codes (e.g. IRSN)

Model developers for severe accident codes (e.g. RUB)

Regulators (USNRC) and Expert organizations (e,g, GRS)

Test results will be used for validation of severe accident codes by developers and users. Furthermore, they contribute to the general understanding of the high-temperature degradation of the new ATF materials.