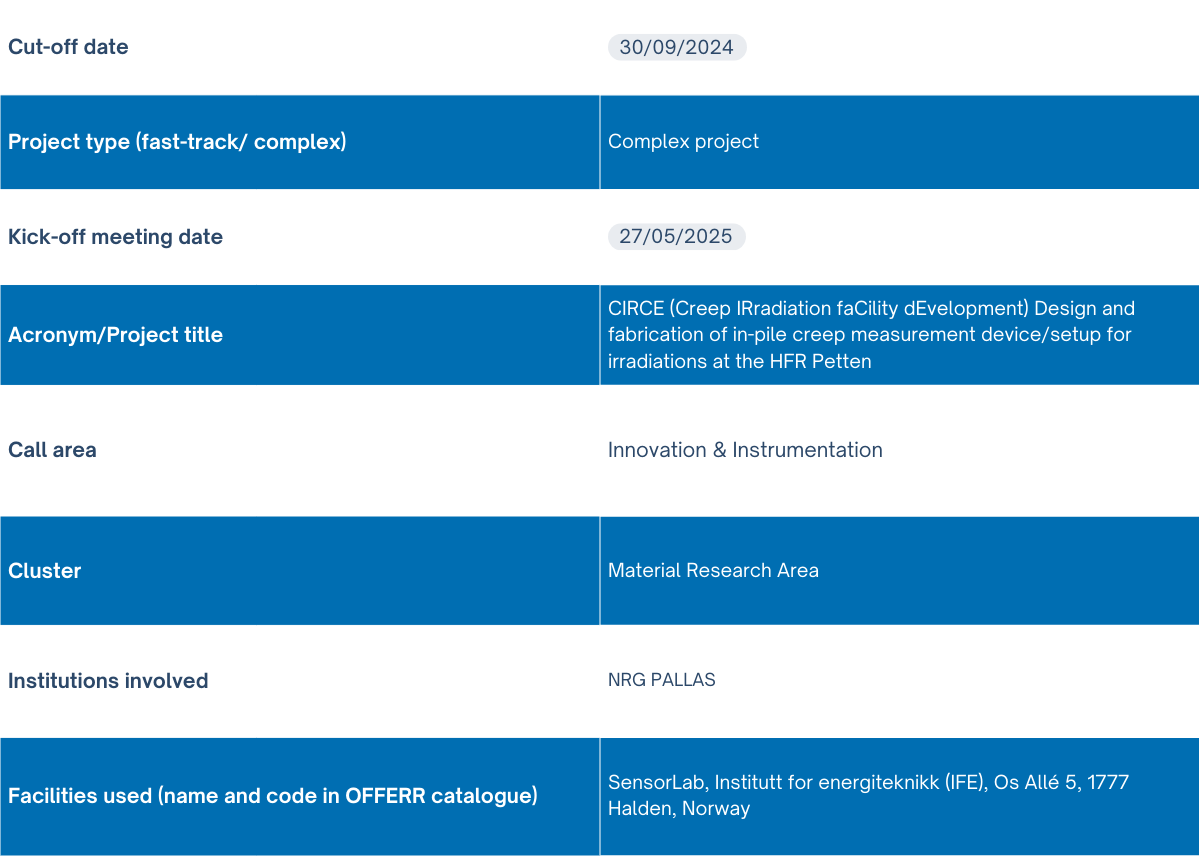

CIRCE Project

What is CIRCE?

Structural materials used in nuclear reactor cores age due to a combination of displacement damage, transmutation, and temperature-induced processes. This project is motivated by a need for measurements of an in-pile behaviour of nuclear materials. The design of two in-pile creep measurement setups is covered in the project.

(i) High-temperature tensile creep. Advanced reactors will operate at high temperatures of 400-750 °C. Within the FIDES-II program hosted by the OECD/NEA, a HITEC project aims to address a high-temperature irradiation behaviour of candidate advanced reactor structural materials. To perform such measurements, an experimental rig will be needed in which a tensile load is applied to alloy samples, which are also connected to a radiation-hard displacement sensor.

(ii) Clad creep measurements. Creep measurements on cladding tubes can provide information on the strain during a power increase, stress relaxation behaviour in steady-state conditions, and the extent of a possible ratcheting effect during consecutive reactor start-ups. Generally, Zr-based cladding materials in nuclear reactors are subjected to irradiation growth and creep. Creep is a slow deformation at constant volume of a material that is subjected to a stress below the yield stress. Irradiation growth refers to an isotropic volume increase in an unstressed material caused by the formation of irradiation-induced defects. Due to current need to validate several new cladding materials for LWRs, it is important to perform an extensive examination of growth and irradiation creep behaviour of new cladding materials. In order to enable this, the setup for biaxial dimensional measurements on cladding tubes will be designed by and fabricated by joint efforts of IFE’s SensorLab and NRG PALLAS.

Objectives

The aim of this project is to expand capabilities at the HFR Petten with experimental setups for in-pile creep measurements in collaboration with IFE’s SensorLab. In this context, two typical Halden capabilities are targeted: First, a setup for in-pile tensile creep measurements at high temperature (650 °C) to investigate structural materials for Gen-IV reactors. And second, a setup for in-pile measurements of the diameter and length of cladding tubes, allowing to gauge clad creep as well as axial creep or/and growth in a limited space under inert gas atmosphere.

(i) In-pile tensile creep at high temperature. The current objective is to prepare a design for in-pile creep measurements based on an existing design for thermal creep measurements in an oven, for realization in the context of the FIDES-II program.

(ii) Cladding creep. The current objective is to design and fabricate a prototype device to allow functioning tests in a furnace setup. Following qualification, a similar design will be used to perform in-pile clad creep measurements in the HFR reactor which will be transferable to the PALLAS reactor, currently being built at the NRG Petten location.

Main outcomes

- A design of an in-pile tensile creep setup using IFE’s LVDT-based sensors and matching with HFR geometry and conditions (engineering and drawings).

- A design and fabrication of an out-of-pile setup for clad dimensional measurements using IFE’s LVDT-based sensors.

Interest for use of reached results

(i) In-pile tensile creep: CEA, FRAMATOME, EPRI, INL

(iI) Cladding creep: ENUSA, Westinghouse