COATED Project

What is COATED?

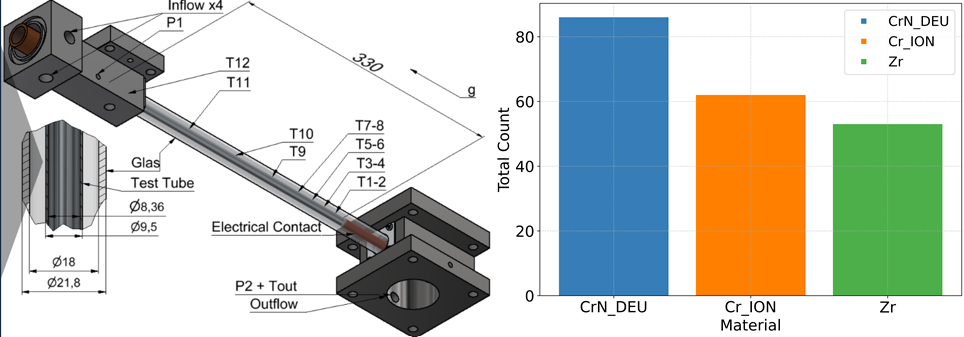

This project aims at critical heat flux (CHF) investigation during flow boiling on accident tolerant fuel (ATF) material used in nuclear reactors. The User’s team will provide their experimental sample of chromium coated fuel cladding which will be investigated at the Infrastructure’s team facility capable of repeatable measurements of CHF under various inlet conditions to provide sufficient data matrix for further analyses. Experimental results of ATF material will be also compared to classic cladding materials previously tested at the selected facility. Test sample will not be analysed only from the thermohydraulic point of view but also from the surface characteristics site, which as shown recently is strongly connected to a boiling process. Such thermohydraulic analysis of ATF material is an active research topic of interest not only in User’s team country but worldwide. Additionally, according to the EU taxonomy, these materials should be used in every new nuclear reactor after 2025, which is very relevant for the User’s country. Since there is only limited possibility of such measurements in User’s country and there is a need for them in the User’s team principal researcher’s PhD project, the User’s team reached to the Infrastructure’s team via the OFFERR project.

Objectives

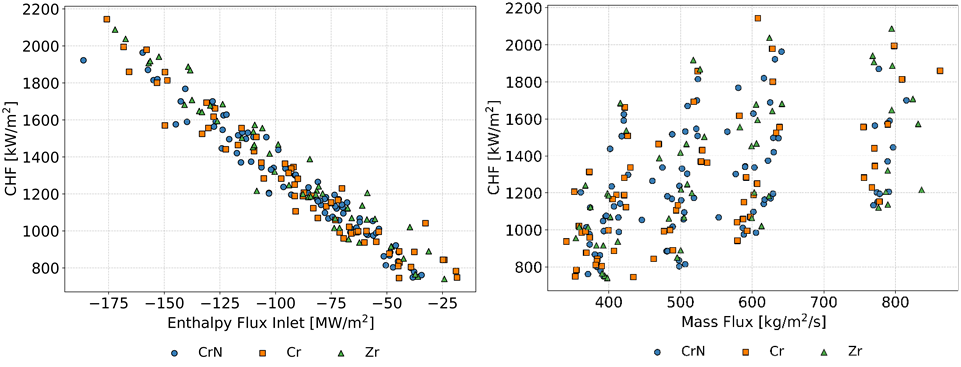

The main objective is to broaden CHF database at various pressure, mass flux, and inlet temperature conditions both on chromium-coated Zr-based alloys that are considered ATF cladding candidates and the standard zirconium alloy cladding. This will allow for a direct comparison of both materials tested at the same facility using the same methodology. Zirconium-based alloys are the reference cladding material to date. These alloys will be tested in the as-received state to provide reference baseline data. In addition, thin protective Cr-based coatings will be deposited on the outer surface of these alloys to allow the study of the CHF for coated materials. There are many types of Zr-based alloys as well as protective coatings that can be deposited by several methods. This work will be focused on standard PWR Zircaloy-4 coated using a magnetron sputtering technique with high-purity chromium. The CHF results will be further analysed by combining the CHF results with detailed microstructure characterization on both coated and uncoated surfaces. Additionally, the CHF database will be created with a focus on both low pressure and low flow, which is characteristic of some small modular reactor designs and accident conditions of light water reactors. Moreover, detailed boiling properties like bubble departure diameter or nucleation site density will be measured for selected operating conditions.

Main outcomes

As mentioned above, accident tolerant fuels are together with critical heat flux investigation an active research topic of interest. The first outcome of this project will be publishing a joint article. The broaden CHF database both on zirconium alloy and ATF chromium coating can be used to create more suitable CHF correlations for either ATF cladding materials or fuel rods under various conditions and especially under low pressure and low flow. The measurement of boiling parameters would lead to more precise modelling using advanced simulation techniques like computational fluid dynamics (CFD) in which new models can be implemented based on these experimental results. Finally, yet importantly the results of CHF measurement on ATF cladding materials are one of the main goals of dissertation thesis of principal researcher from the user’s team.

Publications

-

High-Speed Imaging and Analysis of Nucleation Site Density on Nuclear Fuel Claddings, Proceedings of 21st International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH 21) – published

-

High-Speed Imaging and Analysis of Nucleation Site Density on Nuclear Fuel Claddings, 21st Multiphase Flow Conference, Poster – presented 11/2025

-

Study on Critical Heat Flux on Accident Tolerant Fuel Coatings – PhD thesis, I/2026 expected

-

Experimental and computational investigation of Accident Tolerant fuel surfaces during boiling. – I/2026 expected

Interest for use of reached results

Czech Technical University – PhD thesis,

Paul Scherrer Institute – input data for CFD calculation,

Karlsruhe Institute of Technology – broadening experimental database